Home > Company Introduction

Company Overview

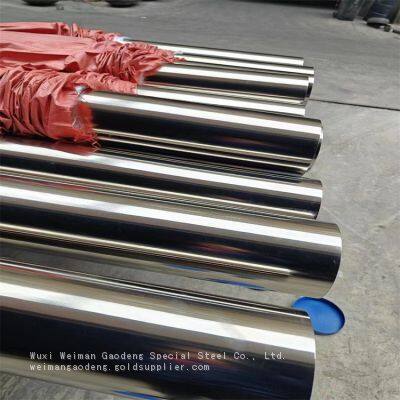

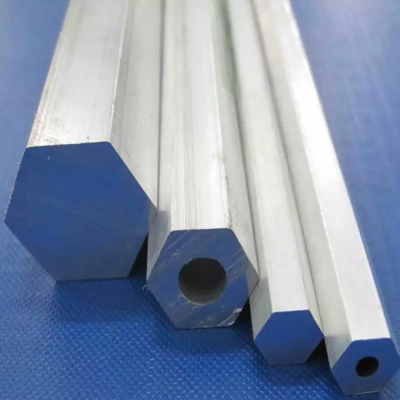

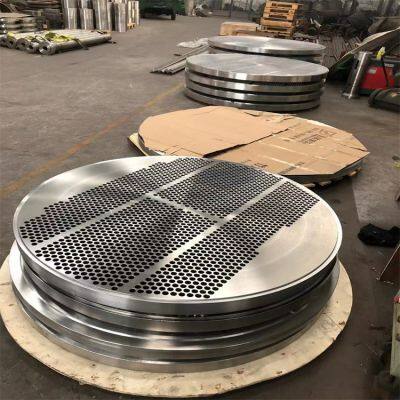

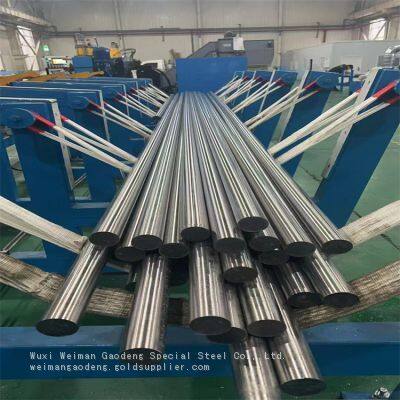

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1. Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2. Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3. Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4. Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

-

ManufacturerBusiness Type

-

2017Year Established

-

1,000-3,000 square metersFactory Size

-

US$5 Million - US$10 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

101 - 200 People Total Employees

-

11-20 People Sales Staff

-

5-10 People Quality Inspectors

-

US$5 Million - US$10 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shanghai, Ningbo, Lianyungang, Suzhou Port of Shipment

-

Titanium Main Industry

-

Quality ControlInternational Approvals CE Mark (CPR Regulation) for structural steel. REACH Registration for restricted substances (e.g., SVHC). Lloyd’s Register certification for marine-grade stainless steel. Titanium-Specific Compliance NADCAP Accreditation: For aerospace titanium heat treatment and non-destructive testing. ROHS/EN71 Compliance: Titanium consumer products (e.g., sports equipment) tested for heavy metals. Testing & Traceability Full-Spectrum Analysis: Bruker Q4 TASMAN spectrometer verifies titanium alloy chemistry (e.g., Al, V, Fe). Batch Traceability System: QR codes provide real-time access to mill test reports (MTRs) and heat numbers. Sustainability 95% of production waste recycled, aligned with EU Green Deal objectives. Why Choose Us?✅ Reliable Supply Chain: Direct partnerships with top-tier mills (e.g., Baowu, JFE) ensure stable raw material sourcing.✅ Technical Support: On-site engineers available for installation guidance and failure analysis.✅ Flexible Solutions: Customized packaging (e.g., seaworthy wooden crates) and logistics plans. Contact us today to discuss how Wuxi Weiman Gaodeng can support your next project with premium special steel solutions.

Quality ControlInternational Approvals CE Mark (CPR Regulation) for structural steel. REACH Registration for restricted substances (e.g., SVHC). Lloyd’s Register certification for marine-grade stainless steel. Titanium-Specific Compliance NADCAP Accreditation: For aerospace titanium heat treatment and non-destructive testing. ROHS/EN71 Compliance: Titanium consumer products (e.g., sports equipment) tested for heavy metals. Testing & Traceability Full-Spectrum Analysis: Bruker Q4 TASMAN spectrometer verifies titanium alloy chemistry (e.g., Al, V, Fe). Batch Traceability System: QR codes provide real-time access to mill test reports (MTRs) and heat numbers. Sustainability 95% of production waste recycled, aligned with EU Green Deal objectives. Why Choose Us?✅ Reliable Supply Chain: Direct partnerships with top-tier mills (e.g., Baowu, JFE) ensure stable raw material sourcing.✅ Technical Support: On-site engineers available for installation guidance and failure analysis.✅ Flexible Solutions: Customized packaging (e.g., seaworthy wooden crates) and logistics plans. Contact us today to discuss how Wuxi Weiman Gaodeng can support your next project with premium special steel solutions. -

Our ServicesSpecialized in High-Precision Special Steel SolutionsWe provide customized materials and value-added services for global industries, ensuring compliance with international standards (ASTM, EN, JIS, API): Stainless Steel Food-Grade 304/316L Super Duplex Stainless Steel UNS S32750 ASTM A312 and EN 10216 Nickel-Based Alloys Incoloy 800H ASTM B407 Hastelloy C276 ASTM B622 Alloy Steel Pipes P91/P92 ASME SA335 WB36 EN10216-2 Titanium Alloys Ti-6Al-4V AMS 4928 Medical-Grade Titanium ASTM F136 Forgings Heavy-Duty Forgings: Produced via 4000-ton hydraulic presses, including wind turbine shafts (up to 20m length) and nuclear reactor components. Processing & Testing Capabilities Factory-Made Fabrication Welded elbows/flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT) Custom-cutting services for plates (max thickness 120mm) and pipes (OD 20-1200mm). Advanced NDT Services Ultrasonic Testing (UT) to EN 10228-3, detecting internal defects as small as 0.5mm. Magnetic Particle Testing (MT) for surface cracks, certified by SGS and BV. Rapid Logistics strategically located warehouses in Wuxi, ensuring 48-hour delivery to major Chinese ports

Our ServicesSpecialized in High-Precision Special Steel SolutionsWe provide customized materials and value-added services for global industries, ensuring compliance with international standards (ASTM, EN, JIS, API): Stainless Steel Food-Grade 304/316L Super Duplex Stainless Steel UNS S32750 ASTM A312 and EN 10216 Nickel-Based Alloys Incoloy 800H ASTM B407 Hastelloy C276 ASTM B622 Alloy Steel Pipes P91/P92 ASME SA335 WB36 EN10216-2 Titanium Alloys Ti-6Al-4V AMS 4928 Medical-Grade Titanium ASTM F136 Forgings Heavy-Duty Forgings: Produced via 4000-ton hydraulic presses, including wind turbine shafts (up to 20m length) and nuclear reactor components. Processing & Testing Capabilities Factory-Made Fabrication Welded elbows/flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT) Custom-cutting services for plates (max thickness 120mm) and pipes (OD 20-1200mm). Advanced NDT Services Ultrasonic Testing (UT) to EN 10228-3, detecting internal defects as small as 0.5mm. Magnetic Particle Testing (MT) for surface cracks, certified by SGS and BV. Rapid Logistics strategically located warehouses in Wuxi, ensuring 48-hour delivery to major Chinese ports -

Company HistoryFrom R&D Focus to Global Special Steel Solution Provider 2003 Foundation: Launched to do R&D and material solutions for power plant boiler steel, partnering with Baowu/Wuhan Iron and Steel on high-temp alloys for 600MW+ projects. 2015 Tech Upgrade: Added NDT for alloy steel pipes, meeting ASME SA335 standards to prep for global expansion. 2017 Compliance Win: Got ISO 9001:2015, API 5L, EU PED certifications; joined SGS to build accredited testing facilities, stepping into international markets. 2019 Global Cooperation: Teamed up with Germany’s DMV Mannesmann on nickel-based alloy supply, supporting Saudi Aramco’s Jazan Power Plant. 2023 Export Growth: Serves clients in MENA, Europe, North America; recognized as a key player in Jiangsu’s foreign trade. Key Tech Bits: 2018: Made WB36 tubes for CNPC’s LNG projects. 2020: Used EBW for titanium, hitting ≤0.01mm accuracy. Ops & Sustainability: Runs automated lines covering stainless steel (316L/S32750), nickel alloys, titanium, 20m forgings; 95% waste recycled. Partners This path shows a tech-driven shift from an R&D startup to a global solution provider, focusing on compliance and practical partnerships.

Company HistoryFrom R&D Focus to Global Special Steel Solution Provider 2003 Foundation: Launched to do R&D and material solutions for power plant boiler steel, partnering with Baowu/Wuhan Iron and Steel on high-temp alloys for 600MW+ projects. 2015 Tech Upgrade: Added NDT for alloy steel pipes, meeting ASME SA335 standards to prep for global expansion. 2017 Compliance Win: Got ISO 9001:2015, API 5L, EU PED certifications; joined SGS to build accredited testing facilities, stepping into international markets. 2019 Global Cooperation: Teamed up with Germany’s DMV Mannesmann on nickel-based alloy supply, supporting Saudi Aramco’s Jazan Power Plant. 2023 Export Growth: Serves clients in MENA, Europe, North America; recognized as a key player in Jiangsu’s foreign trade. Key Tech Bits: 2018: Made WB36 tubes for CNPC’s LNG projects. 2020: Used EBW for titanium, hitting ≤0.01mm accuracy. Ops & Sustainability: Runs automated lines covering stainless steel (316L/S32750), nickel alloys, titanium, 20m forgings; 95% waste recycled. Partners This path shows a tech-driven shift from an R&D startup to a global solution provider, focusing on compliance and practical partnerships. -

Our TeamExpert Team & International Collaboration Driving Quality Through Technical Excellence Leadership Team Mr. Sang Le (CEO): 20+ years in special steel, with expertise in EU/US market compliance. Dr. Li Wei (Chief Metallurgist): PhD in Materials Science from Tsinghua University, specializing in creep-resistant alloys and titanium metallurgy. Technical Staff 12 ASME-certified NDT Level III inspectors: Capable of interpreting UT/MT results per AWS D1.1 and EN10228. 5 NADCAP-qualified engineers: For aerospace-grade titanium processing, ensuring compliance with NAS410 standards. Global Partnerships Collaborate with SGS and BV for third-party audits, ensuring alignment with ISO 17025 standards. Maintain long-term agreements with German DMV Mannesmann and Spanish Tubacex for premium alloy sourcing.

Our TeamExpert Team & International Collaboration Driving Quality Through Technical Excellence Leadership Team Mr. Sang Le (CEO): 20+ years in special steel, with expertise in EU/US market compliance. Dr. Li Wei (Chief Metallurgist): PhD in Materials Science from Tsinghua University, specializing in creep-resistant alloys and titanium metallurgy. Technical Staff 12 ASME-certified NDT Level III inspectors: Capable of interpreting UT/MT results per AWS D1.1 and EN10228. 5 NADCAP-qualified engineers: For aerospace-grade titanium processing, ensuring compliance with NAS410 standards. Global Partnerships Collaborate with SGS and BV for third-party audits, ensuring alignment with ISO 17025 standards. Maintain long-term agreements with German DMV Mannesmann and Spanish Tubacex for premium alloy sourcing.